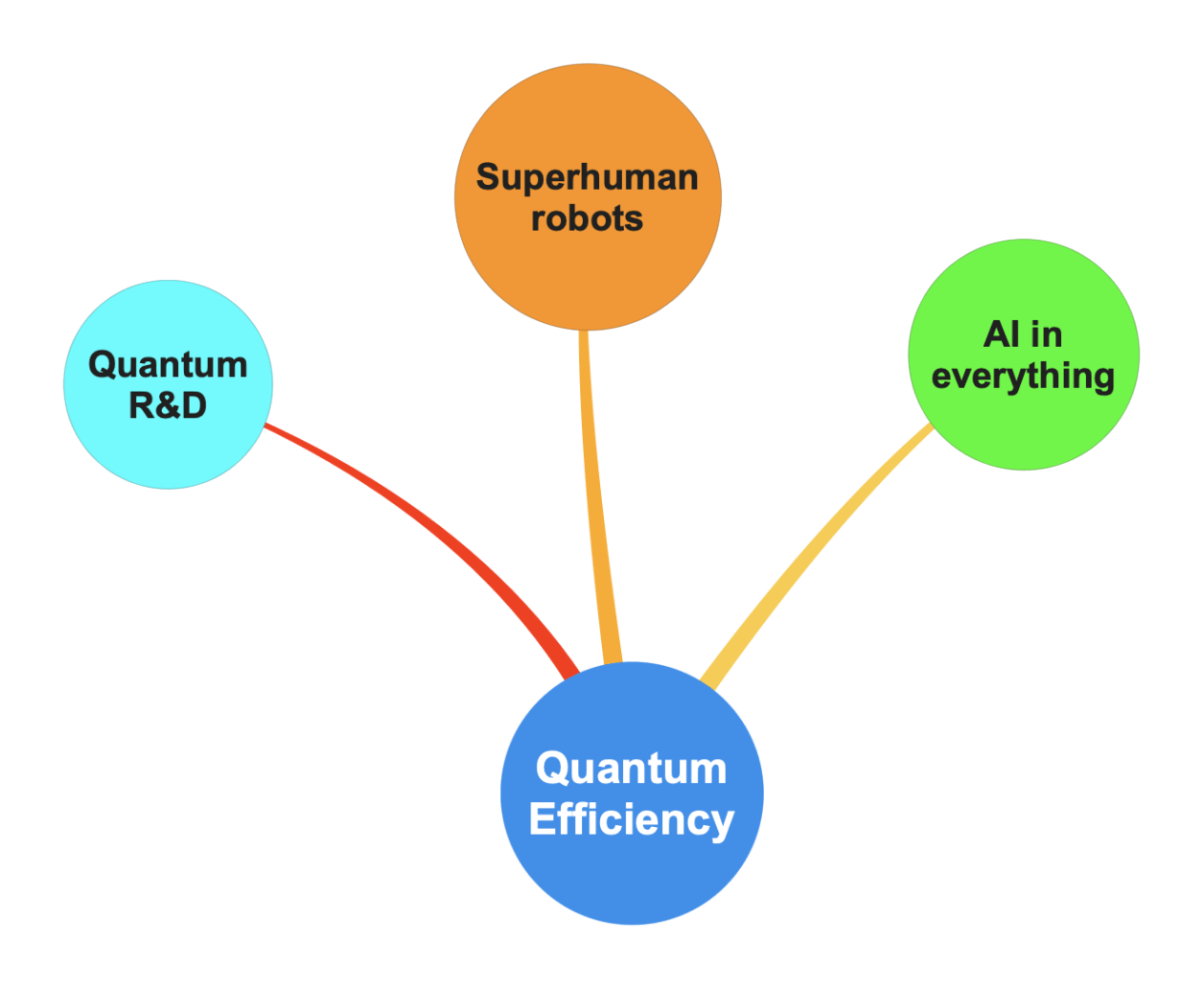

Mission: To bring everything you need to achieve Quantum Efficiency

Research and development to solve problems, superhuman robots that humans can rely on, and AI in everything.

Research and development to solve problems, superhuman robots that humans can rely on, and AI in everything.

Data driven AI based control systems beat hand crafted traditional real time control systems in chemical, food, and manufacturing industries.

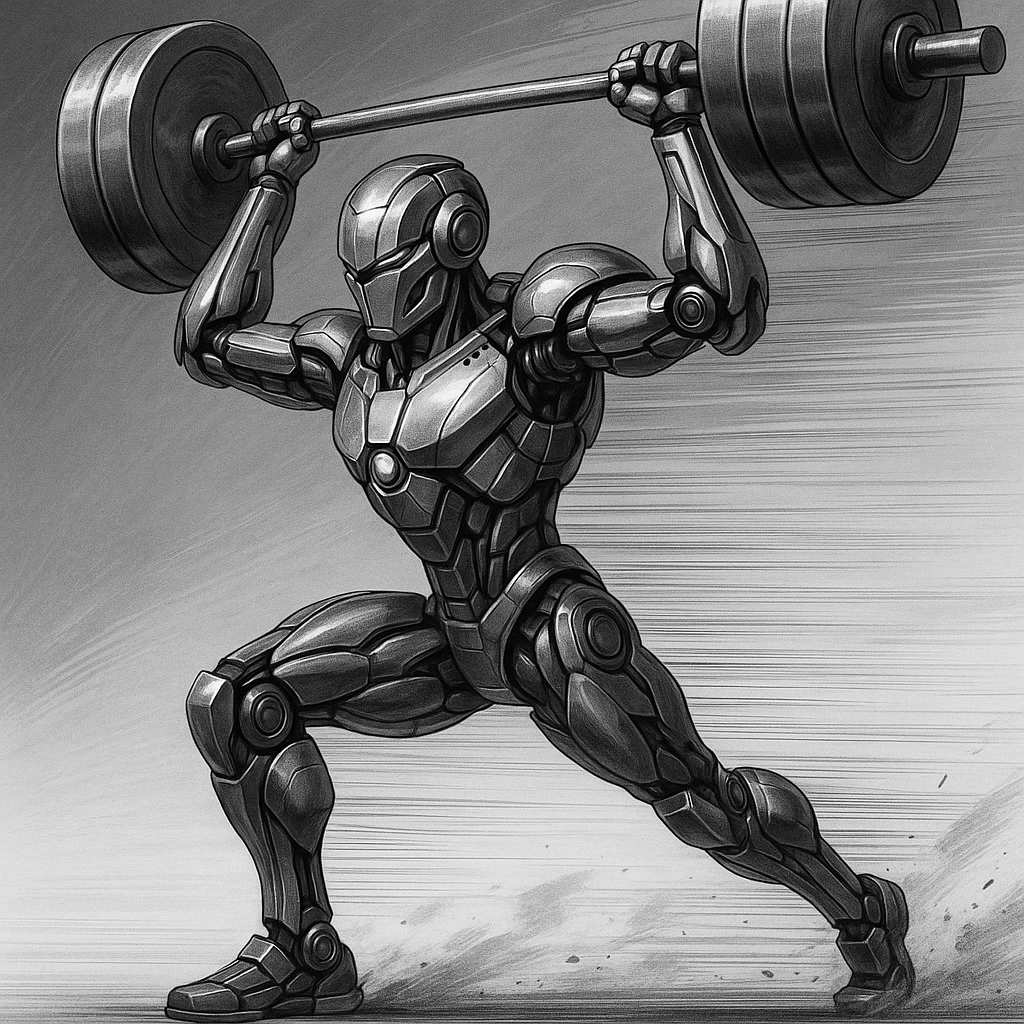

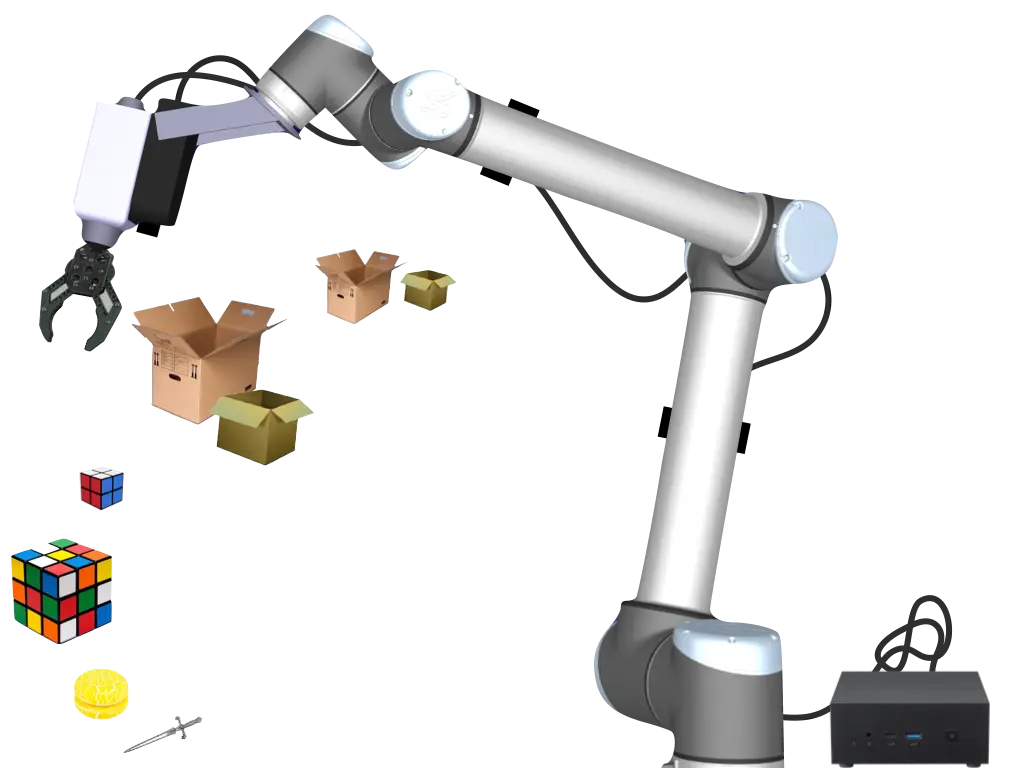

Robots, robot integration, and intelligent AI driven robotic operation.

Expertise in scientific data analysis and machine learning.

Customer experience focused technology expertise in app development, cloud technologies, and AI.

Qi R&D's mission: to solve problems and innovate customer focused solutions

To that end, we bring together a vast network of innovators, scientists, and businesses, and integrate them through our unique innovation processes.

The robots that have superhuman abilities to lift weights and still move with incredible speed and precision. We bring a lot of things together to achieve this vision.

Qi Innovation's mission is to bring AI to everything.

AI is changing our life but there is a lot to do to make it efficient. It can be brought to everything we do. That's the goal driving our innovation.

Introducing the world's fastest learning visual artificial intelligence - Quantum VLC. With Quantum VLC, you can program robots by showing objects and speaking to them. You can "tell" a robot what to do when it "sees" something.

For example, you can train a robot to sort toys in large or small boxes depending on their size, just by showing the process once. VLC can save time, money, and effort and improve precision in robotic operation.

Watch the video: real time learning in VLC

With Quantum VLC, you can program robots by showing objects and speaking to them. You can "tell" a robot what to do when it "sees" something.

Camera can be trained to detect cracks and quality defects with a few mouse clicks.

Camera can be trained to detect changes in viscosity of liquid and turn ON or OFF specific processes through connected PLCs. This kind of training can be done with only a few mouse clicks.

Teachable machine can quickly learn to identify minute impurities like hair and thread in turmeric powder, withy only a little bit of training. It gets smarter as it sees more samples over time. This tool can benefit food, chemicals, and pharmaceutical companies.

With Quantum VLC's fastest learning AI, you can improve quality, minimize waste, and reduce cost

With our visual feedback driven closed loop control technology, you can detect changes in viscosity and color of fluid and automatically adjust operating parameters to maintain desired quality

Qi's Visual AI detects micro and macro defects in tablets and capsules in real-time on a manufacturing plant. Visual AI can enhance manufacturing process, improve product quality, and make sorting and packaging operation more accurate.

Measurement of machine parameters on a manufacturing plant creates a feedback loop that improves awareness, cost efficiency, learning, and decision-making. Advanced plant monitoring can improve strategic planning and collaboration between different departments and experts.

Managing a manufacturing plant is challenging because of scale, complexity, accessibility, compatibility and integration issues, data management and analysis, calibration, and cost. You need a comprehensive measurement system that uses advanced automation and sensor technologies, adopts standardized measurement protocols, and provides integrated data management tools.

Our Quantum RTDT (Real Time Data Tracking) is a technology platform designed to achieve one and only objective: to help you keep your manufacturing plant running at the highest efficiency.